Quality Control

AOTOP always adheres to strict quality management to deliver reliable and safe products worldwide!

Quality That Stands up to Scrutiny

AOTOP factory has passed ISO 9001 certification and uses it as a guiding principle in our daily production processes. We collaborate with well-known display and lens suppliers, including Innolux, CSOT, BOE, M-Star, Sony, and Sharp, and our quality has been proven reliable by our customers. We believe in the power of standardized processes, from raw material inspections to finished product testing and everything in between.

AOTOP’s 4-step quality management system includes:

Verification of the qualifications of raw material suppliers

Self-procurement of raw materials and inspection

Standardized process quality control

Standardized process quality control

Attention to Every Detail

We care about the quality of our cameras and displays, which is why we focus on every detail of each part that makes up a perfect camera or display.

Camera and Monitors Mainboard Driver

We use EMC-certified camera and monitor mainboards. Every component must be correctly placed and soldered to maintain the camera and display’s operation under a certain maximum power, correct voltage regulation, and correct power factor.

Camera

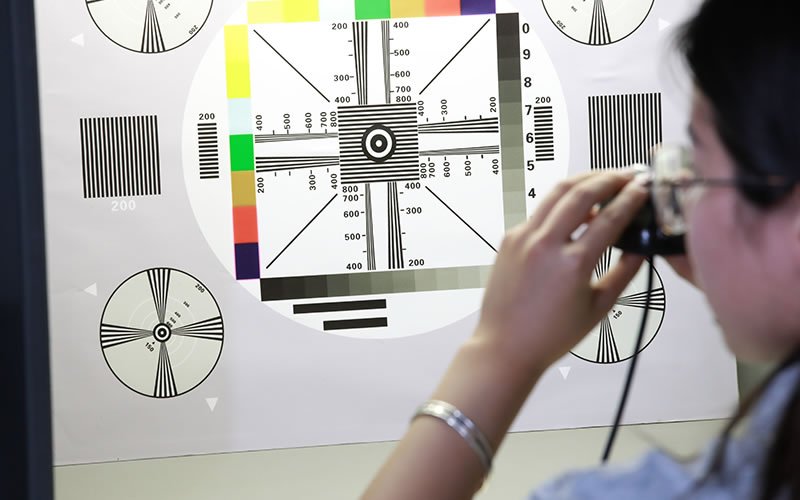

Camera manufacturing requires expertise and caution. From adjusting the lens angle to checking correct colors, inspecting the lens installation to wire connections, we have detailed standards for each inspection step, and by doing so, we can eliminate any defective cameras 100%.

Monitor

Car monitor manufacturing requires expertise and caution. From high and low-temperature display screens to checking the color effect of the screen, checking the bright spots of the screen to the connection of the driver board, we have detailed standards for each step, and by doing so, we can eliminate any defective displays 100%.

Camera and Monitor Appearance

The appearance of the camera and display forms the first impression, so we never ignore any minor defects. Whether it’s fur made through casting or injection molding processes, uneven spraying, size or specification deviations, we do not allow any such situations to occur, nor will we let any products with such defects enter the next process.

Sample Testing

Ensuring Quality for Mass Production

AOTOP product test center is designed to meet the highest standards of quality and precision. Our test center is housed in a spacious environment, complete with an industrial-grade anti-static floor and 6S on-site management method, ensuring clean and organized workspace. All test equipment is placed scientifically and rationally to facilitate efficient testing procedures.

Our test center is fully equipped with a wide range of experimental equipment, allowing us to test all aspects of our vehicle camera and monitor systems, from spare parts to finished products. We have comprehensive testing capabilities, ensuring that our products meet the most rigorous quality standards.

Our test include functional testing, durability testing, environmental testing, and more. We use advanced testing equipment and software to ensure that our products are reliable and perform well under all conditions. All products are thoroughly inspected and tested before being shipped to our customers, ensuring that they meet the highest quality standards.

Photometry Test

Accurate camera illumination specification

Electronic Performance Test

Verifies stability & function

High-Low Temperature Test

Simulates extreme climates

Electrical Parameter Test

Measures key electrical parameter to ensure product meets design specifications

Drop and Vibration Test

Simulates shock & vibration to assess product reliability

Extreme 72 Hour Waterproof Test

Verify product water resistance & long-term sealing performance